Rösler Rutten Turbine reduserer kostnadene enormt for SSAB

Reduction of turbine down times by 90% and spare part costs by 50%. blades easily reaching 30,000 to 40,000 blast hours, before having to be replaced.

Rutten Long Life blast turbines combine better performance and higher equipment uptimes with significantly reduced operating costs

„RetroFit“ increases productivity and operational efficiency

To stay competitive in today’s global markets companies must constantly strive for further optimization of their manufacturing operations. The Retrofitting of shot blast machines by Rösler with Rutten Long Life blast turbines will significantly improve the cost efficiency of virtually any shot blast operation. Due to their unique design these patented high performance turbines yield energy savings of over 25% . At the same time, the service life of the throwing blades of 30,000 up to 40,000 hours results in significantly higher equipment uptimes and drastically reduces the costs for maintenance and spare parts. Many companies like, for example, the Swedish steel producer SSAB or the German foundry Heunisch GmbH have taken advantage of the Rösler RetroFit program to increase the productivity and efficiency of their shot blast operations.

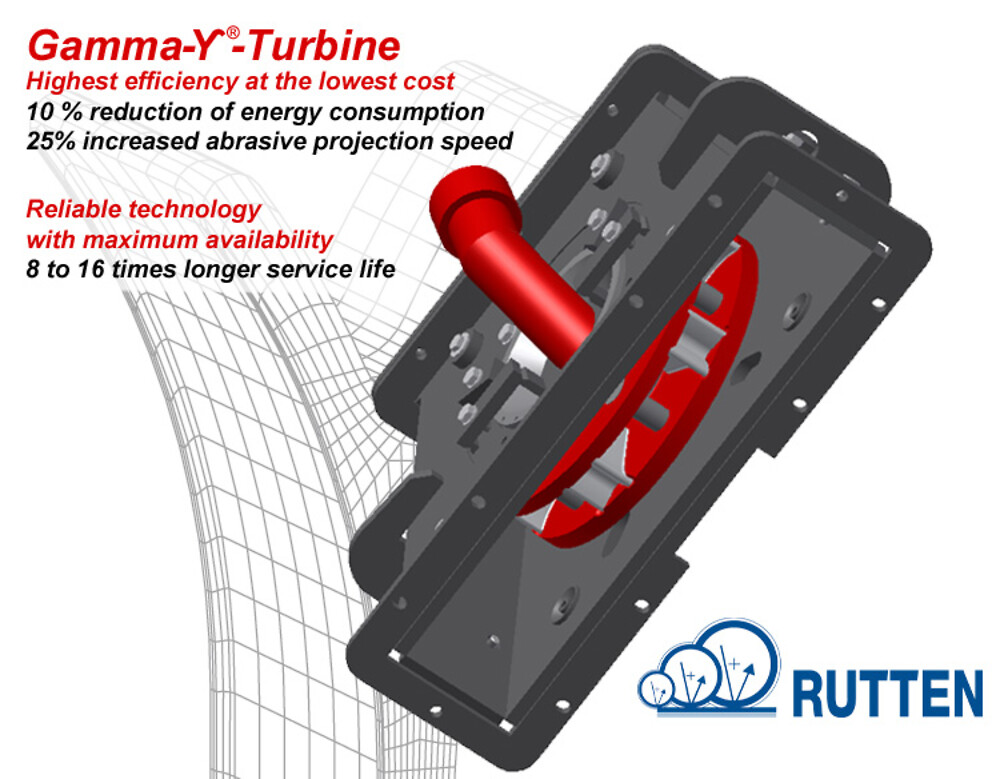

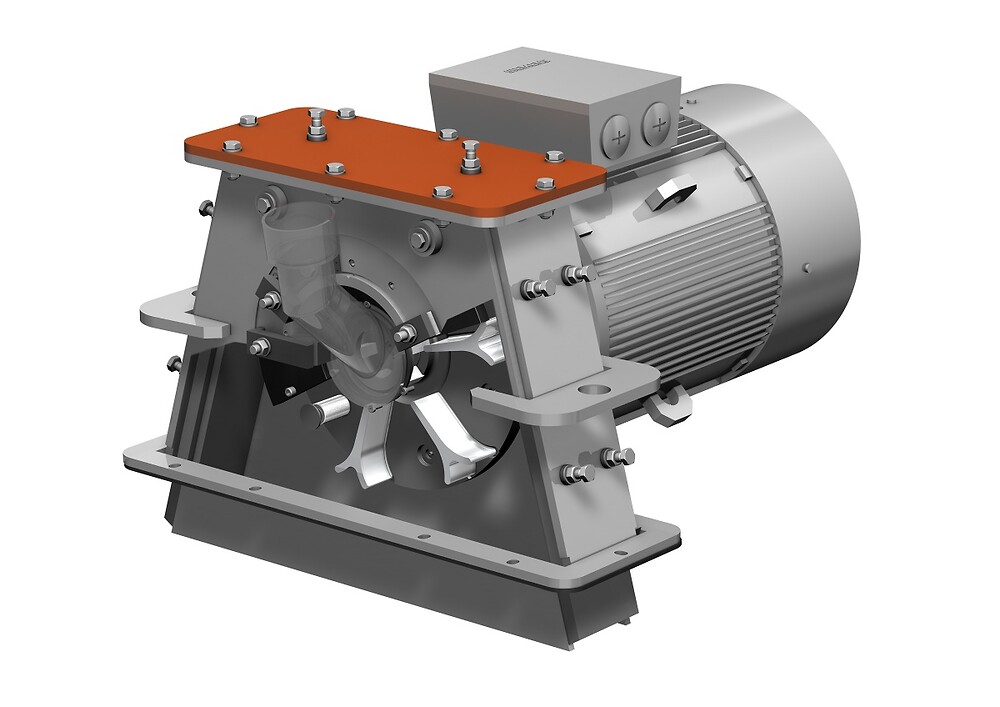

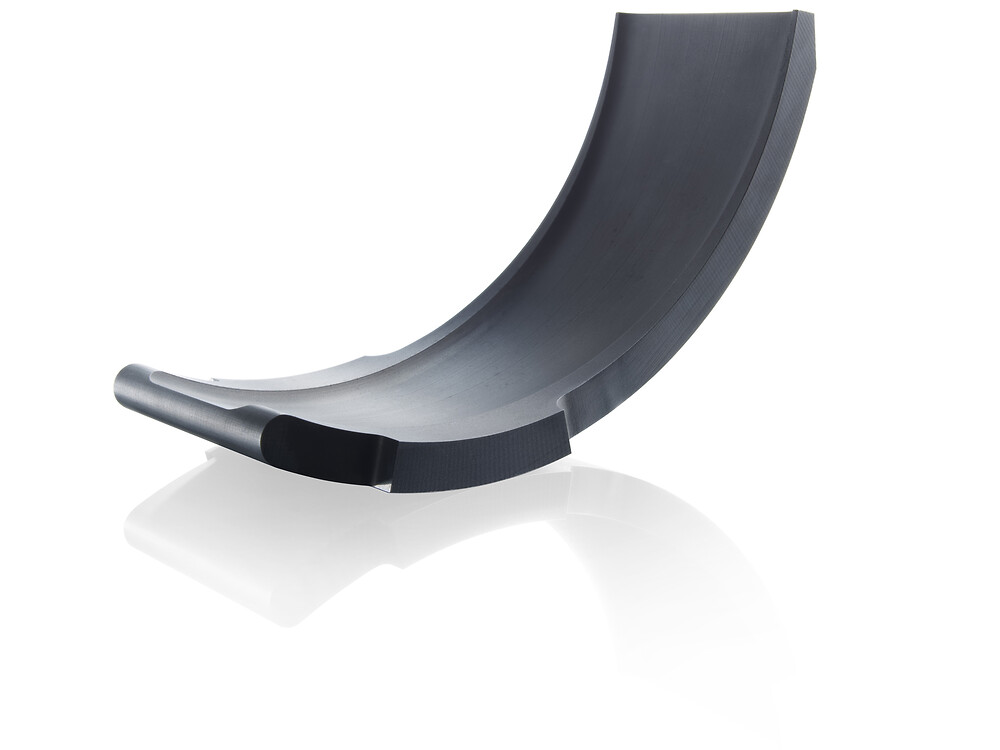

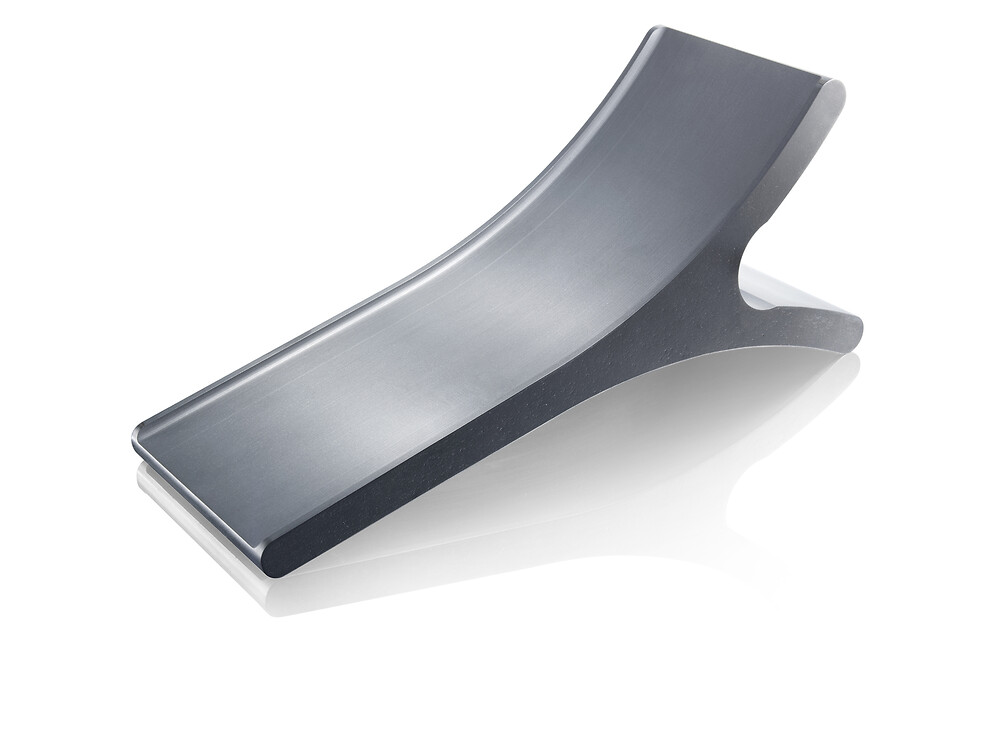

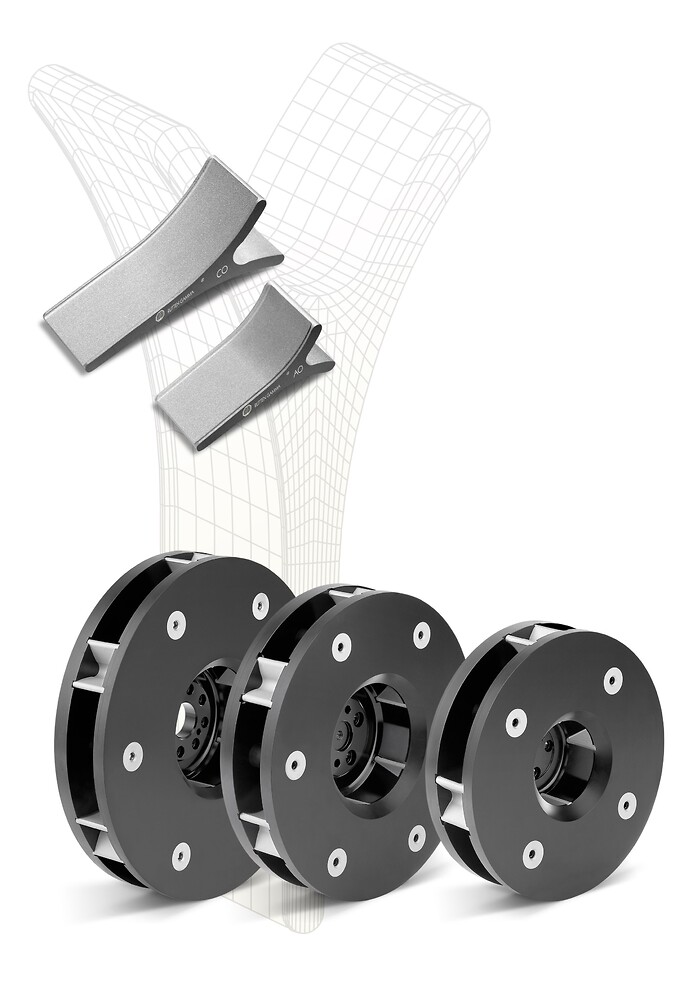

Surface treatment machines are generally subject to a certain wear rate. This is especially true for shot blast equipment running in multiple shifts often resulting in long equipment down times with a significant loss of production and extremely high maintenance and operating costs. Another important cost factor is the usually very high energy consumption of these machines. In many cases a systematic equipment modernization will not only provide state-of-the art technology, but will also greatly improve the overall cost efficiency. Within the scope of its “TuneUp” program, the Rösler Oberflächentechnik GmbH has created a service organization that deals exclusively with the optimization and, the technical overhaul of existing shot blast machinery - irrespective of make or model. This program also includes the retrofitting of blast machines with Rutten Long Life turbines for which Rösler is not only holding the respective patents, but is also the manufacturer and exclusive supplier of spare and wear parts. These highly unique high performance turbines are available with Curved-C and Gamma-Y throwing blades. The latter have two working surfaces arranged in a “Y” shape allowing shot blasting in both rotational directions of the turbine.

Reduction of turbine down times by 90% and spare part costs by 50%

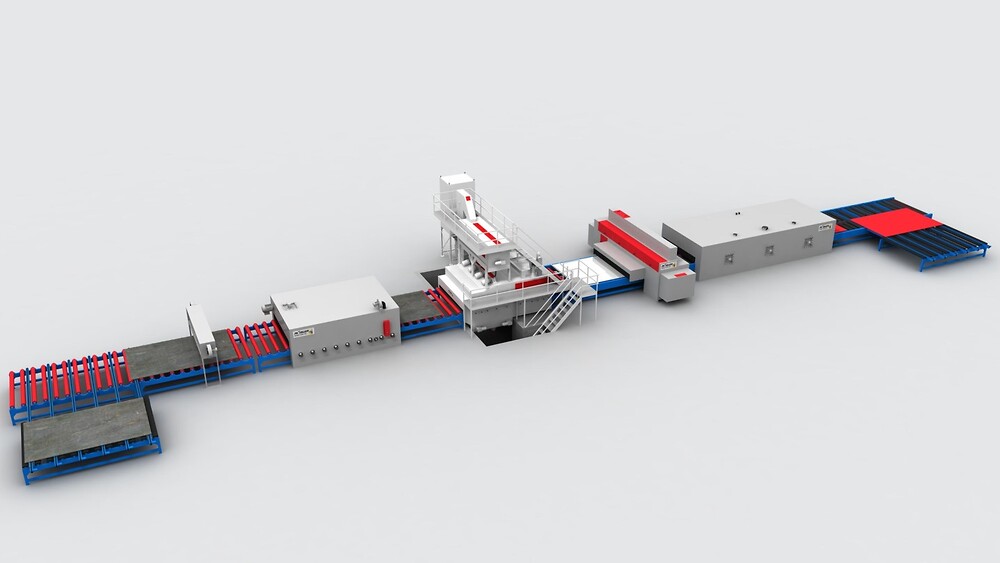

The Swedish SSAB AB, one of the world’s leading suppliers of high strength steel, decided to modernize the shot blast equipment at its SSAB EMEA plant in Oxelösund. The production of the company with around 8,100 employees, located in 45 countries, amounted to about 5,500 thousand metric tons of crude steel in 2012. The Swedish plant in Oxelösund is considered to be one of the most important producers of tempered steel in the world. Production line 2 manufactures mainly wear resistant Hardox steel plates and sheets. Prior to tempering the raw material must undergo a blast cleaning process for which the line is equipped with two shot blast machines. Two additional shot blast machines are integrated into the painting line. Five maintenance & repair teams working 24/7 (7 days per week round the clock) ensure that the line runs smoothly with a minimum of down time. Kent Forslund, who as maintenance manager of production line 2 is responsible for the scheduling of maintenance work and the cost efficiency of the equipment, explains: “With all of our four blast machines from three different suppliers the original blast turbines were generally wearing very fast. This required a lot of maintenance work, which frequently resulted in long equipment down times and very high spare part costs. In addition, it could happen that a blast turbine completely disintegrated causing damage to the other blast turbines and the blast chamber. For this reason, we have equipped all our shot blast machines with Long Life Rutten blast turbines”.

The original 32 blast turbines on all four shot blast machines at SSAB EMEA were replaced with Rutten Long Life blast turbines, each with an installed power of 22 kW. The decision for this important RetroFit program with Gamma-Y high performance blast turbines was based on their excellent operational characteristics. This includes the extremely long service life of the throwing blades easily reaching 30,000 to 40,000 blast hours, before having to be replaced. The throwing blades in conventional blast turbines have an expected life of on average 2,000 hours. The maintenance manager continues: “The wear rate on the Rutten turbines is extremely low so that the overall maintenance work and the maintenance related down times could be drastically reduced. In addition, our overall spare part costs were reduced by about 50%”. In addition, the Rutten turbines also contribute to a much higher productivity: The special design of the patented throwing blades ensures a highly “fluid” movement of the blast media. This, in combination with an optimized blast media transfer onto the blades, produces a much higher media flow rate and throwing speed compared to conventional blast turbines operating at the same RPM’s

and with identical turbine diameters. The overall effect is a greatly improved finish of the blasted surfaces resulting in shorter processing times and lower media consumption. Kent Forslund proudly summarizes his experience: “I think that by retrofitting our blast machines with Rutten Long Life turbines we have reduced the down times of our shot blast equipment by 90%”

Reduction of energy consumption by 25%

Another important aspect of the Long Life turbines is that due to their higher operational efficiency they require less energy: The specified shot blast results can be achieved with a lower horse power motor, which helps reduce the overall energy consumption. This was one of the major reasons why the foundry Heunisch GmbH decided to go ahead with the RetroFit program. At its four manufacturing locations this company produces carbon steel and aluminum components with the gravity die-casting technology. The range of services extends all the way from engineering consultation to surface treatment. Efficient manufacturing operations ensure that the foundry remains highly competitive. At its Steinach plant where custom engineered castings from GJL, GJS and NI-RESIST materials are made for drive trains, marine applications, general equipment & compressor manufacturing and fluid handling components, Heunisch has equipped three shot blast machines of different brands with Long Life blast turbines. Jürgen Frank, the manager of the foundry maintenance department at Heunisch Guss, remarks: “To make our shot blast operations more efficient we are utilizing the Long Life blast turbines in two spinner hanger machines and one tumblast machine”. These machines are equipped with a total of 17 blast turbines. The foundry also decided to utilize the Gamma-Y turbines. Jürgen Frank continues: “To precisely quantify the benefits of this modernization program is very difficult; but we are absolutely certain that retrofitting our shot blast machines with Rutten turbines resulted in cost savings of at least 25%”.

Quick amortization

At SSAB EMEA as well as at Heunisch the RetroFit program has significantly contributed to considerable cost savings and optimization of the overall production process. Based on the individual shot blast equipment configuration at the customer the Rösler TuneUp team determines which Long Life blast turbines are most suitable for achieving the customers’ specified shot blast results, and which cost savings and amortization times can be achieved with the RetroFit program. To emphasize Rösler’s commitment to this program and its expected cost savings the company offers a special warranty by offering the customers the option to return the turbines within a certain time period: If a customer is not satisfied with the results of the RetroFit program, Rösler will re-mount the original blast turbines free-of-charge within the specified time period and return the full purchase price for the Long Life blast turbines. The replacement of the original turbines with Rutten Long Life turbines requires an investment amounting to about 30 – 35% of the costs for the new shot blast machine. This investment is amortized in two to three years by drastically reduced costs for energy, maintenance and spare parts, much lower equipment down times, by considerably lower blast media consumption. Of course, once a customer needs to replace the old shot blast machine, the new machine can be equipped with the existing long Life turbines. Retrofitting an existing shot blast machine with Long Life turbines greatly enhances this machine’s operational efficiency and is in many cases a cost effective alternative to purchasing a brand new blast machine. Customers should also consider if the performance of an existing shot blast system could be improved with additional peripheral equipment, or if the equipment uptime could be greatly improved by the installation of optimized wear protection packages in the critical wear areas.

For mer informasjon kontakt thomas.bech@tbmaskin.no